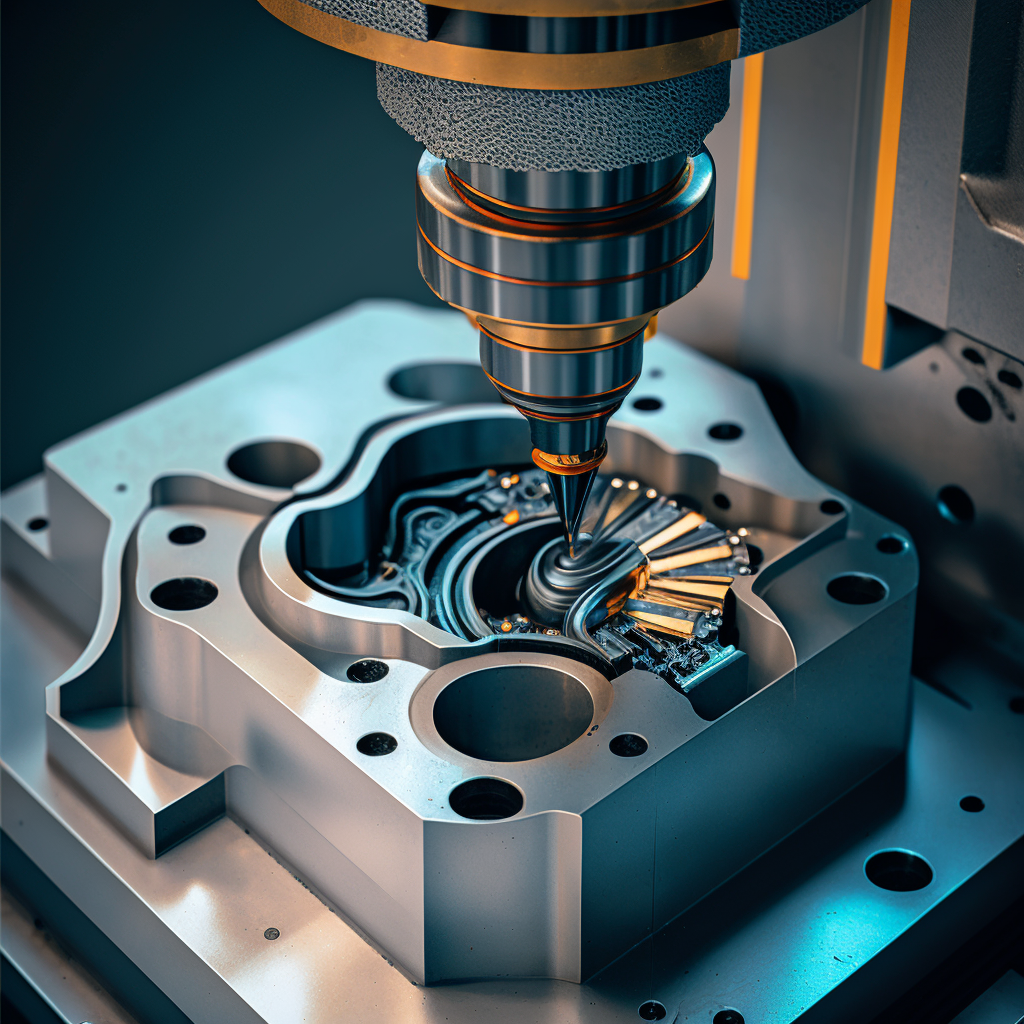

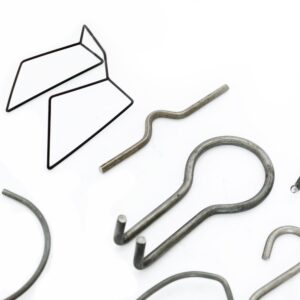

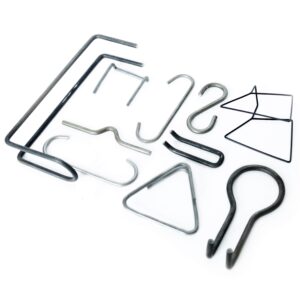

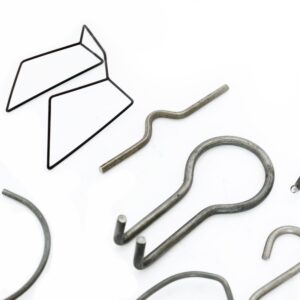

PRODUCTION OF PRECISE AND COMPLEX COMPONENTS

PITERPARTS CNC

Milling, turning, cutting and machining of materials using modern CNC (Computer Numerical Control) machine tools

Milling, turning, cutting and machining of materials using modern CNC (Computer Numerical Control) machine tools

PiterParts implements CNC (short for Computer Numerical Control) services - computer numerical control - for manufacturing precision parts. CNC technology enables the automation of manufacturing processes. The use of Okuma and Mazak CNC machine tools allows for the precise execution of many repetitive operations and the creation of complex shapes with high accuracy using CAD/CAM systems.

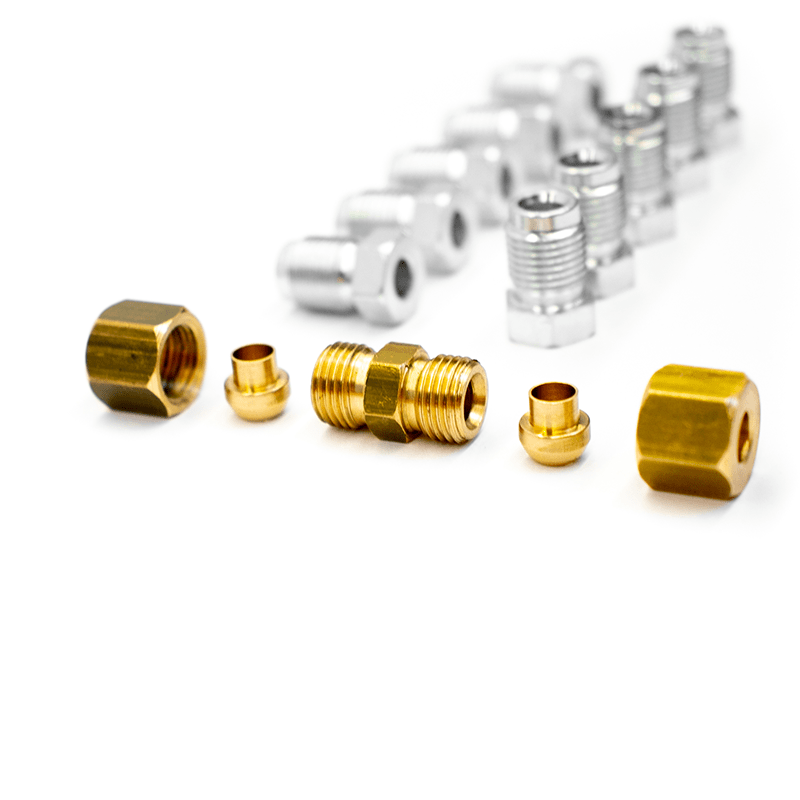

PiterParts CNC customizes its services to meet the individual needs of its customers, offering a team of highly-skilled machine operators, customized solutions and a state-of-the-art CNC machine park equipped with world-class numerical control machine tools.

The CNC cutting process, carried out using numerically controlled machines, is all about ensuring that materials are cut accurately and reproducibly with minimal risk of error, which is extremely important for many industries where precision, quality, speed and automation are key to achieving optimum results. CNC turning is a material machining process in which a cutting tool, such as a lathe, is used to remove material from a workpiece and create a cylindrical surface. The process is controlled by a computer that precisely determines the direction and speed of the tool movement, as well as the depth and shape of the groove. CNC turning is often used to produce precision parts and components such as shafts, pins, axles and other cylindrical components used in the automotive, aerospace and medical

We have all the tools to prototype and produce parts